This construction technique is old, but its green and cost effective applications have added a new dimension to the construction industry. Monolithic, reinforced concrete thin shells, Binishells are lifted and shaped by air pressure. Elliptical in section, these range between 12 and 40 metres, and could be built in 60-120 minutes. They were invented in the 1960s by Italian architect Dr Dante Bini, a pioneer in automated building construction, who built 1,600 of them in 23 countries. Bini was inspired by the pioneering work done by four masters — Felix Candela, Heinz Isler, Buckminster Fuller and Frei Otto. Since then, six new systems of construction of Binishells have been devised, each addressing a different need and adding to the ease of building column-free large and organic spans. The primary highlights of this system of construction are speed, very high building strength, affordability, locally sourced green materials with little or no waste, and reducing carbon footprints and construction schedules by more than 50 per cent. Each Binishell starts as a two-dimensional shape on the ground, ringed by a wooden form into which an air bladder (pneumoform), reinforcing steel rebar and a load of concrete is placed. As the concrete sets, an air pump fills the bladder and a concrete dome begins to rise from the earth. An hour later, the concrete has hardened, the bladder is deflated, removed for reuse, and the building’s soaring shell is ready for inspection and interior construction. Except for a few additives, these are constructed from the same concrete and rebars that are available off the shelves in local stores. Improvements to the original system include greater architectural flexibility, compliance with international building codes, simplification of the construction process and integration of the latest green building technologies and materials like green roofs and passive heating/cooling technologies. Most importantly, Binishells are resistant to all natural disasters like very high winds and even flooding, and have survived extreme environments such as lava, ash and constant earthquake tremours for more than 50 years. The shape has advantages beyond strength as it is also inherently aerodynamic.

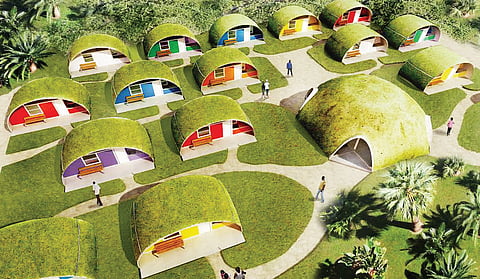

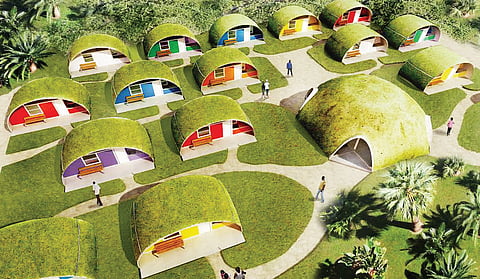

This simple but radical construction system results in organic buildings of practically any scale. Applications of Binishells are limitless. These can be used in designing and spanning stunning high-end custom residences, schools, gymnasiums, military bases, or commercial and civic buildings like sports stadiums, resorts, and airports. Due to its permanent design at very low cost, instant construction, easy implementation and resistance to natural disasters, Binishells are most sought after in developing nations and as a disaster-relief housing construction system. With 25 per cent of the world’s population living in sub-standard shelters, Binishells will definitely have a huge impact.

Binishells have very efficient building envelopes that reduce energy use by as much as 75 per cent or more, as compared to traditional construction. The embodied energy is less than 50 per cent of traditional structures while the cost is one half. It eliminates the need for skilled labour and expensive construction equipment on site. Binishells require minimal upkeep and can be easily re-purposed. With so many advantages under their domes, Binishells are the much needed transformative construction system in today’s world.