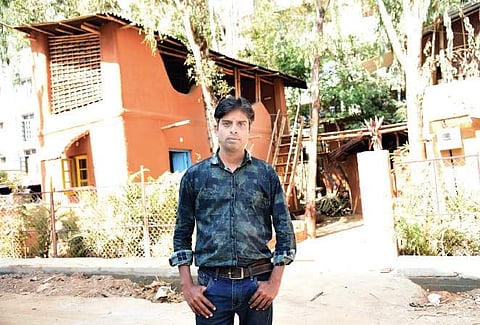

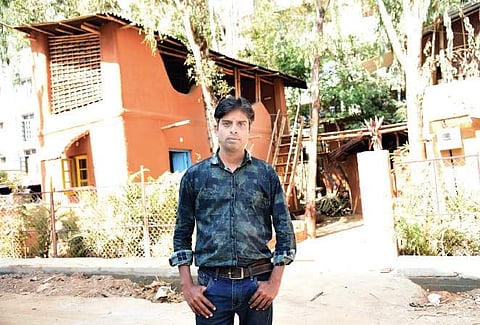

BENGALURU: Can a blade of grass replace steel? Yes, says 38-year-old Bengalurean Babu K Iyer. This businessman, who makes and sells bamboo furniture, has also made his entire factory building from bamboo and mud bricks.

“There are varieties of bamboo that are stronger than mild steel (the steel used for construction),” he says. “The steel has a strength of 23,000 psi (or the weight it can take per square inch) while a particular variety of bamboo, called Guadua Angustifolia, has a tensile strength of 28,000 psi.” The bamboo is therefore called the “vegetable steel”.

Babu started his bamboo business Bamboo Pecker in 2009, and then he was making furniture, now he also consults for construction using bamboo.

Midnight Hunt

His love for the grass started way back in 1998. Babu was on the lookout for ‘wild’ lampshades for a function and his search lasted till 12:30 in the night to get one piece. Babu realised that bamboo products are difficult to locate. Babu, who had tried his hand at various businesses, decided there is a market for bamboo furniture.

When he started, his friend and an architect suggested that he build at his factory also from bamboo. Babu went along with it and had his first bamboo office and workspace in 2009. “But that building was razed,” he says, “by the landlord and without a notice.”

In 2015, one of his customers gave him land to reconstruct the factory, near KR Puram, and Babu decided to stick to the ‘green’ side. “There were 22 eucalyptus trees in the plot,” he says, “we made a plan that keeps all of them standing... there are two or three trees inside the work area.” This time too, the factory was made from mud bricks and bamboo. It has a work area, store room, Babu’s office, treatment facility, toolroom and space for employees to stay.

Age-old Technique

Susanth CS, Senior Designer and Head of Center for Bamboo Initiatives, has seen the growth of Bamboo Pecker from the beginning. He calls Babu’s construction method “very good” and hopes more people will follow his example. “His factory has even withstood few monsoons without a problem,” says Susanth, “most people worry that mud walls will not withstand the rains. But mud has been used for a long time in this country.”

The design expert says that, while there are other bamboo-based constructions in the city, Bamboo Pecker’s is different because it uses no or minimal concrete. “I have used concrete only in my office and in the work area,” says Babu. “It was to build the raised foundation to keep water from seeping in.” But this concrete too was sourced from waste at a nearby construction site. “We crushed the waste and seived it, and used mostly the mud from it,” says Babu.

Breathing Walls

Bricks were made from mud that is dug out at various construction sites. “We mixed that mud with crushed rock and a fermented solution of jaggery, lime and kadukka (or Terminalia Nebula) for the mixture and then left it in the mould to dry in the sun,” says Babu. The bricks are not compressed or baked. “This is a method that has been used since time immemorial, even for dams like the Mullaperiya dam... I am willing to wager anything that bamboo was used as reinforcement in the dam,” says Babu.

A small mud house that ‘breathes’. “In a closed concreted room, your breath bounces back from the wall... but in this factory, the mud walls filter the air because it is porous,” he says.

1,000 Shoots from One

Bamboo is one of the most sustainable materials because it regenerates quickly. “You cut from a tree and then it takes 20 years for another tree to grow in its place,” says Susanth. “But from one plant, you can get atleast a 1,000 culms.”

“Bamboo grows in multitudes when planted,” says Babu. “In a year, a bamboo plant can give five to six shoots. When the seeds are planted, they take time to adjust to the soil condition... once they have, there is no stopping the grass’ growth.”

While all this -- the eco-friendliness and near perennial nature of the grass – sounds good, the stumbling block is in its availability. “The material is cheap but sourcing it is expensive and time consuming,” says Babu. “You need the forest department’s permit to cut even privately grown plants, then you need a permit to transport them, then you need a record of your storage and if you want to move the stock, you need to apply for other permits.”

Babu is part of a group that promotes the use of bamboo. “It is difficult for me, despite being part of this council and a businessman... sourcing bamboo would be a headache for a common man,” he says.

‘Invisible Gods’

There is always the threat of fungal infection and pest attack with the grass that belongs to the sugarcane family. “There is sugar in the stem and pest, which lay eggs in the stem, tend to stay on for the food or sugar,” says Babu. “They flood the interiors of the plant... They are called the ‘invisible gods’ because they are everywhere and we don’t know where they come from.” Babu has a treatment system that breaks their food chain.

The cut bamboo sticks are treated using a method called Boric Borax. This involves use of a salt, milder than cooking salt, that is mixed with water and then allowed to penetrate through the inner walls of the bamboo culms, cutting pests off from their ‘sugar’ foods.

(Inputs from Rakshnna Pattabiraman)