The quaint two-storied building of Rathna Offset Printers on Peters Road is hard to miss. Fifty years old and one of the pioneers in printing technology, the company has stood the test of time. It’s evident from how the name has been rooted in customer-centric service and quality at affordable prices until today, in the fiercely competitive print space. It has grown steadily into a 200-strong workforce. Print is alive and so is their business.

Past forward

The family-owned business is currently shared by six partners. Three bothers — B Rajkumar, B Ashok Kumar, B Suresh Kumar — and their children — Nakul Rajkumar, A Aadithya Sharan, and Akshara Suresh Kumar. “My father had five brothers. The eldest one, Rajalingam, laid the foundation stone of what we have today. Around 1968, there was an International Trade Fair at Anna Nagar. He purchased the first single-colour Russian offset machine. After which, he opened a small space in Border Thottam in early 1970. In 1974, he purchased six grounds from an Anglo-Indian in Royapettah, the current space. However, he left the company in 1977,” says Rajkumar.

CHENNAI : The brothers are from Sivakasi, known for its printing industry. However, they ventured into this industry after completing their engineering degree in Chennai. “Our hometown is the frontrunner of printing industry. It has a rich legacy and has been functioning effectively for decades. The dry weather makes it conducive for the printing process,” he says.

The company purchased its second printer in 1978. The present partners officially took over the company in June 1985. They purchased their third printer and first multi-coloured machine in 1988. “There were established printing companies when we got into the field. We were new to this and picked up a few tricks from our cousins who were already into the business in Chennai. Our approachable and amicable attitude along with communication skills helped us get orders for textbooks and magazines from 1990. We used to give the quotation then and there.

We learned everything on the field and that’s how we earned the trust of our clients. In fact, we explained the costing and competitive pricing that garnered us patrons, eventually. Our work spoke for us,” he shares. The company has around 800-900 clients and more than 2,000 digital clients. There are 75-90 regular customers. The owners opened another printing and packaging unit in a bigger area at Poonamalle in 1994. The publishing press unit was opened in 2010.

Calendars, diaries, posters, brochures, coffee table books, invitations, envelopes, cards, tabloid and flyers are a few among their range of finished products. “Our main clientele is the digital divisions of the publishing houses and print on demand,” says Aadithya. Every time a new machine is purchased, the employees go through multiple stages of training until they are familiarised with their equipment.

Behind the covers

The sound pre-press, press and postpress infrastructure make this company one-of-a-kind. It’s 5 pm. The offset-printing unit on the ground floor is dingy and bustling with activity. The scent of ink, glue and unused paper fills the air. The sound of huge printing machines running simultaneously is deafening. The colour scheme of inks in all the printers is standard — cyan, yellow, magenta and black. Bundles of paper are loaded and unloaded. Hot and freshly printed sheets emerge out of the machine rapidly and get collected in a basket for the next stage.

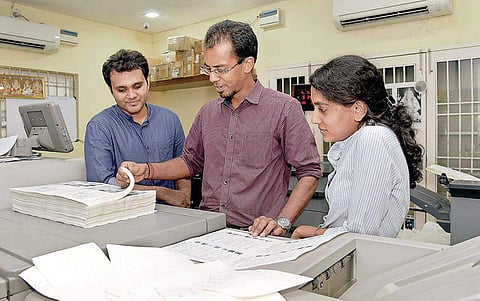

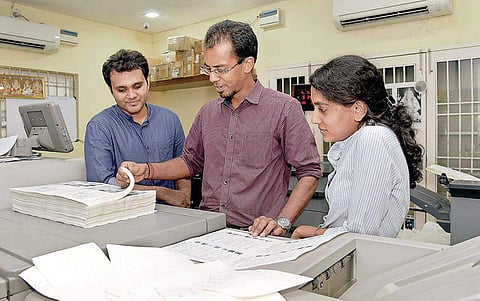

On the first floor is the prepress section that is relatively calm and bright. The printed output in various sizes goes through stages of cutting, binding and laminating. They’re put together into textbooks, novel covers and magazines,and given a glossy finish. We notice workers meticulously involved in various stages of production. Heaps of finished products to be dispatched are arranged in corners. The second floor has a space that takes care of web and digital work, and print on demand projects.

They have sheet-fed offset, web-fed offset and digital machines. “Each step is carried out in a specially designed equipment to ease the process. There’s a machine for trimming the edges of a book, one for binding a book and stitching it together, and then the wrappers are manually added. It’s fascinating how every step delivers a perfectly completed product,” says Aadithya.

The company has an advanced set of commercial printers that include sheet-fed machines, saddle- stitching machines, folding machine, knife-cutter and single gelatin printing machine. “This is an unorganised, cost- and labour-intensive industry. From printing to packaging, one has to keep hopping around to different places for the final output.

But our place is a one-stop solution and this is the reason we have loyal customers for years now. There’s business round the clock. We are busy when schools reopen and then there’s one festival or the other. As far as the future is concerned, I think the print industry is flourishing. We need to have more units in our country to develop the industry,” says Rajkumar.