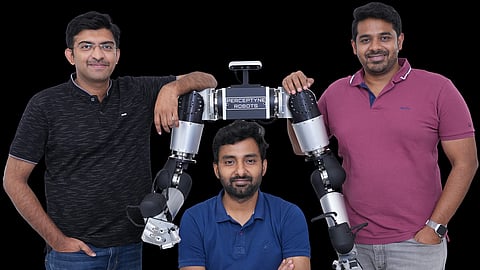

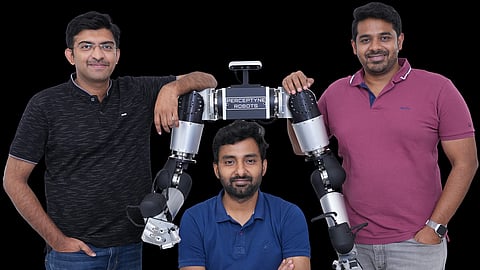

Robots — they’ve fascinated us ever since the ’70s and ’80s, haven’t they? Big, bulky metallic figures capable of mass destruction on Earth. We watched with bated breath and fear in our eyes as the heroic Autobots and the evil Decepticons brought their war to Earth in the movie Transformers (2007). While the fictional human Sam Witwicky (played by Hollywood star Shia LaBeouf) saves the day and does so in the next two movies, three Hyderabad-based innovators have been building robots — not to stand by and watch a war — but to revolutionise automation across industries. Raviteja Chivukula, Jagga Raju Nadimpalli, and Mrutyunjaya Sastry tell us what it takes to build a robot, why they stand out, and whether or not robots are going to take over the world.

Excerpts

Can you tell us about Perceptyne?

Each of us (Raviteja, Jagga Raju, and Mrutyunjaya) brought over a decade of experience from diverse domains including aerospace, defence, automotive, and biomedical engineering.

What we observed was that decisions to automate were typically high-stakes, long-cycle investments, often involving significant budgets and months of planning. Despite this, many of these automation initiatives either stalled midway or failed after deployment.

This inspired us to reimagine automation. Instead of overhauling entire systems, what if robots could be deployed like plug-and-play components — seamlessly stepping into existing production lines without requiring major infrastructural changes? Our goal became clear: to create robotic systems that could directly fill in for human workers at individual stations, allowing automation to be adopted quickly, flexibly, and incrementally. And so, we founded Perceptyne, an AI-powered robotics company focused on building semi-humanoid robots capable of performing dexterous tasks, such as product assembly in the electronics and automotive sectors.

What does Perceptyne offer, and what are your robots capable of doing?

There is a popular misconception that a majority of industry tasks are automated. If one goes to an electronics assembly line of a cell phone, many workers will be sitting on either side of a conveyor doing small atomic assembly tasks. These tasks require a lot of dexterity — we are building the technology that can help automate these nimble tasks. We have launched two products: PR-9D, a single-arm robot, and PR-34D, a dual-arm robot. These robots are commercially available to select customers right now.

What does it take to build a robot at Perceptyne?

India still lacks a mature robotics ecosystem — most robotic arms here are imported, and there’s no established supply chain to rely on. So, we design and build every component in-house: from mechanical structures and integrated actuators to firmware, application software, and AI modules.

A robot consists of close to 1,000 unique parts that need to come together. Every part is thoroughly tested before it is put in a robot. Parts are put together to form sub-assemblies which are further thoroughly tested. Once a full robot is made, it is put through several hours of functional testing to ensure the robots operate without any failures. The testing allows us to capture any failures early at our production site and correct them before the robot is shipped to our customers.

We’ve built a full-fledged prototyping facility that allows our engineers to go from idea to physical prototype within a day. While most startups at our stage rely on external vendors, our in-house capabilities let us iterate fast and stay ahead.

Future plans — what else are you planning to build?

What we are building is a platform technology with applications across industries. While automotive and electronics manufacturing are initial go-to markets for us, in the future, we will target industries like pharmaceuticals, industrial-scale food preparation, semiconductors, and so on. Global expansion is very much on the roadmap — our goal is to make Perceptyne a global player in the AI-Robotics era.

What makes Perceptyne stand out from other companies in the sector?

We are the first company in India to build humanoid/semi-humanoid robots from the ground up for the AI era. We are innovating at every layer, be it hardware, perception, control, data collection, and AI, to build a tightly integrated robot that can work seamlessly in various real-world environments.

What are the main challenges that robotics companies in India face?

The robotics industry in India is in its infancy. The required talent to build this cutting-edge product is just getting trained. The silver lining here is that there is a lot of talent that is returning from the US due to various personal and geopolitical reasons. And they are bringing with them all the experience they gained working for some top companies in this space.

From the minds of our readers — will robots replace humans?

Robots will not replace humans; they will empower humans to do more.

We’ve already seen this with industrial automation. For example, automotive factories introduced robotic arms decades ago to handle tasks like welding, painting, and assembly. These robots didn’t eliminate human jobs — they changed them. Workers moved into roles focused on robot maintenance, quality control, and production planning. In fact, the productivity boost led to more cars being made, which created more jobs across supply chains and logistics.

You will see the same pattern repeat across several automation technology innovations: robots take over the repetitive, physically strenuous, or dangerous tasks, so humans can focus on the work that requires adaptability, decision-making, and creativity.