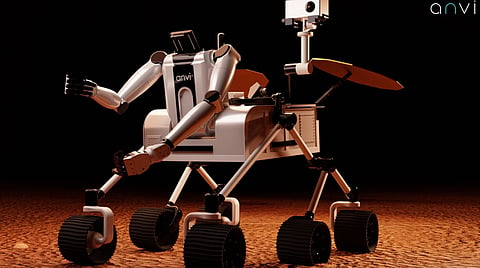

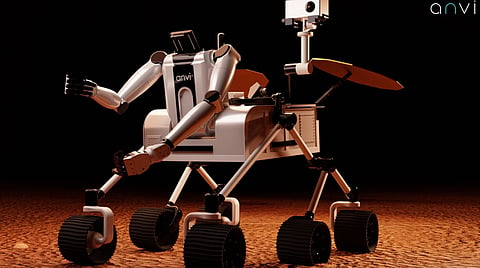

When the Srisailam Left Bank Canal (SLBC) tunnel partially collapsed on February 22, there was widespread chaos, fear, and uncertainty. The NDRF, SDRF, Army and Telangana government got into action mode… along with robots. Yes, you heard that right! The officials employed robots with AI-based cameras as part of the rescue operations. Created by Hyderabad-based Anvi Robotics, these robots have shifted the narrative around robotics in India. While global debates revolve around AI replacing human jobs, Anvi Robotics is proving that robots can serve as life-saving allies, diving into situations far too dangerous for humans.

Following the mission, the team — consisting of Dr Gandham Neelima, co-founder, Nihitha Yedla, director of operations, Vijay Jagadam, director of AI, and Akshay Caringula, director of mechatronics — introduced a specially designed multipurpose rescue robot under ‘Project Suraksha’. It is dedicated to supporting frontline heroes, such as the NDRF, SDRF, and the Indian Army. In an exclusive chat with CE, Dr Neelima sheds light on the SLBC rescue operation, Project Suraksha, and more.

Excerpts

Anvi made headlines during the recent SLBC tunnel rescue operation — can you walk us through that mission? What role did your robots play and what challenges came up?

Well, for Anvi, the SLBC tunnel rescue operation created a flood of mixed emotions. This was one of the most catastrophic tunnel accidents in recent times, and in terms of rescue complexity, it was among the most daunting. When we arrived on-site and assessed the situation, we knew the road ahead wouldn’t be easy. We weren’t sure how far we could push the limits, but we decided to give it everything we had.

Working alongside the NDRF, SDRF, the Indian Army, and the Government of Telangana, our young team of engineers gave their all — day and night. The biggest challenge was time. Disasters demand a war-footing response, but building technology typically takes the opposite route — slow, methodical, deliberate. So we had to understand fast, act fast, and build even faster.

Our robots, built using rapidly available materials, were primarily focused on sludge removal — both hard and soft — inside the tunnel. We also deployed a custom communication system to connect the tunnel interior with our master robot outside. Our AI engines scanned the tunnel’s perimeter, identifying hazards in real time.

Connectivity inside the tunnel was a major hurdle — extremely limited network access made robot communication tough. Space was another constraint; the tunnel’s narrow width left little room to operate without obstructing other rescue teams. And then there were the TBM (Tunnel Boring Machine) parts — massive components that became recurring obstacles as the rescue progressed.

SLBC will always be remembered as one of the most challenging and emotional experiences we’ve faced. In its aftermath, we launched Project Suraksha — a specially designed multipurpose robot built to support our heroes in the NDRF, SDRF, Army, and other rescue units. We will proudly dedicate this robot to the nation on August 15, 2025.

The state government, Indian Army, and NDRF sparked a much-needed shift towards integrating advanced technologies in disaster response, and we are committed to turning that vision into reality. We’re also in talks with both state and Central governments to establish a Centre for Advanced Robotics in Disaster Management, in collaboration with the All India Robotics Association (AIRA).

For years, we’ve watched Hollywood films where futuristic robots come to humanity’s rescue. Until COVID-19, even we believed only Western nations had that edge. But India proved its mettle during the pandemic. Similarly, while we haven’t seen real-life robots swooping in to save the day — yet — we believe that’s about to change. With this new centre, India can lead the global response in times of crisis.

What is the story behind Anvi Robotics? How did the founding team come together, and what sparked the idea to build this company?

Anvi comprises founders of different startups. We have Anvi Robotics, Anvi Space, Anvi Green Energy, Anvi Semicon and Anvi Studios — this is the first time ever that founders in robotics, AI, space tech, hydrogen fuel, semiconductors, and gaming have come together. We all believed that India has to gear up and compete with global technological giants in product innovation.

The core idea behind Anvi Robotics is to build robots which really aid in critical tasks rather than the fancy tasks. With a limited product line, we are building and integrating the most complex tasks with robotics and AI. Surveillance robots, semi-humanoids for multiple industrial applications, humanoid robots and disaster management robots are four products designed and built to address very critical applications.

There is a lot of conversation around AI and robotics replacing jobs — but Anvi seems to be creating solutions for situations in which humans can’t be in. How do you see your work aligning with or challenging the mainstream AI narrative?

At Anvi, we don’t build machines to replace people — we build them to protect, extend, and empower people. Our robots crawl into collapsed tunnels, brave toxic steel furnaces, and roam alien terrain so that human beings don’t have to risk their lives there. Our AI turns torrents of data into clear decisions, freeing engineers and operators to focus on creativity, strategy, and stewardship. Every time we automate a dangerous task, we open room for safer, high-skill jobs in design, maintenance, analytics, and mission control; every rover we land or factory we digitise creates an ecosystem of new roles that didn’t exist yesterday. So, rather than fitting the narrative of AI displacing workers, Anvi is proving that intelligent machines can be humanity’s frontline allies — taking the heat, lifting the weight, and unlocking frontiers so people can do what only people can: imagine, innovate, and inspire.

How do you approach ethics and safety in AI and robotics, especially when your tech is being used in critical operations like rescue missions?

Ethics and safety aren’t departments at Anvi — they’re the first line in every design document and the last check before any system leaves our lab. When lives hang in the balance, we treat every line of code and every servo like mission critical medical equipment: built with failsafe redundancies, real-time self-diagnostics, and human override at a single touch. Our development loop begins with a multidisciplinary ‘red team’ review that pairs engineers with ethicists, rescue professionals, and regulators to stress test worst-case scenarios before a prototype even powers on. We simulate millions of edge cases in digital twins, then rehearse them in controlled field drills alongside the very first responders who will deploy the tech.

Most importantly, we anchor every project to a simple covenant: the machine must always serve and safeguard the human, never the reverse. That means transparent decision logs for AI, strict data privacy firewalls, continuous remote monitoring, and a culture where any employee can halt a deployment if safety feels compromised. By weaving ethical accountability into our hardware, software, and corporate DNA, we ensure that when our robots roll into collapsed tunnels or volatile refineries, the people depending on them can trust not only their strength but their integrity.

From a tech standpoint, what powers your robots? What makes your technology stand out from others in the same space?

At the heart of every Anvi robot lies a hybrid intelligence stack — a ROS-2–based operating system integrated with our proprietary edge-AI co-processors that deliver over 20 TOPS of real-time performance for vision, sensor fusion, and motion planning. Power is drawn from swap-ready solid-state battery packs supported by ultra-efficient supercapacitors, allowing our robots to operate untethered — whether they’re crawling through a flooded tunnel or patrolling factory floors 24/7.

Our sensory array includes LiDAR, hyperspectral cameras, force-torque skins, and gas-sensing MEMS, all feeding into AI engines that continuously evolve through digital-twin simulations and receive nightly OTA (over-the-air) updates.

What truly sets Anvi apart is our mission-grade modularity. One robotic base can host a firefighting arm today, a surgical tool tomorrow, and bolt onto a lunar rover next year — all with auto-calibration in seconds. Every actuator meets global standards and is backed by triple-redundant failsafes and a one-button human override. Plus, our 24×7 Remote Operations Centre can support any deployment, anywhere on Earth. In short, our robots don’t just work harder — they work smarter, safer, and go places others simply can’t.

You have R&D centres in both India and the US. What differences or similarities have you observed between the two when it comes to innovation, access to talent, or tech infrastructure?

The whole idea of having two R&D centres is that with sunrise in Hyderabad and sunset in Houston, our projects chase the clock, creating a 24-hour innovation heartbeat that never sleeps.

We think of our Hyderabad and Houston labs as two chambers of the same heart. Hyderabad beats with the rhythm of rapidfire prototyping and frugal engineering — teams that can conjure a world-class gearbox overnight using local suppliers and sheer ingenuity. Houston answers with deeptech muscle: advanced composites, space grade test rigs, and a network of veteran mentors who’ve put hardware on Mars. The magic happens in the handoff. The vision of our two R&D centres is to ensure that code born at midnight in India gets stress-tested by breakfast in Texas; design tweaks made in Houston are back on a 3D printer in Hyderabad before dusk. That 24-hour innovation loop will let us compress development cycles from months to weeks and ship solutions that are both cost savvy and frontier-ready.

The result is technology that carries the best of both worlds: cost-effective, rugged, and globally scalable — yet powered by frontier science and uncompromising quality. That dual DNA isn’t just a footprint; it’s our launchpad for ideas bold enough to serve the planet and brave enough to leave it.

In a space as dynamic as robotics and AI, how do you stay ahead of the curve? Do you follow a specific philosophy when it comes to innovation?

The whole philosophy is learning from failure — Anvi is a consortium of founders, each of whom have a vast experience with their past successful or failed startup (we all happily admit even if it has failed). As researchers and entrepreneurs, we accept every failure, be it in tech or business, and learn from it to go forward. We give equal importance to ideas from the team, regardless of whether they are interns, full-time employees, or scientists in our labs. We protect these ideas, safeguard them, incubate them, and once we believe the idea is matured enough, we send it to our labs for further implementation.

The other important philosophy we follow is ‘There is no I at Anvi, but always we’. We would like to grow Anvi to compete with global giants in technology and also grow Anvi with all the moral values that Sir Ratan Tata implemented in the Tata group.

Tell us about your team — what kind of culture drives the work at Anvi?

Our team is united by one mantra: ‘Build with purpose, dare with heart.’ Titles disappear at the lab door — an intern can challenge the CTO if the data holds, and a machinist’s hunch can pivot an AI model. We celebrate first principles thinking, midnight brainstorms over masala chai, and failure post mortems where the only blame is on the physics. Every Friday we run ‘ShowtheScar’ sessions: engineers demo what broke, what they learned, and how it will fly higher next sprint. Kindness is mandatory, complacency is banned, and curiosity is rewarded with ownership of the next big problem.

What are your robots currently capable of? And if you could fast-forward 10 years, what’s your dream scenario for Anvi Robotics?

At Anvi Robotics, our mission is to build machines that tackle critical, not just flashy, problems. With a focused product line, we’ve engineered:

Robots for surveillance.

Semi-humanoids for industrial applications.

Humanoid assistants.

Disaster management operations.

Each is designed with purpose, and every deployment addresses high-stakes, real-world scenarios.

Today, our machines:

Patrol smart cities and industrial zones with full 360° situational awareness.

Crawl into collapsed tunnels with six-tonne hydraulic muscle.

Weld, pick, and inspect with sub-millimetre precision.

Learn in real-time through our edge-AI and multi-modal sensor fusion.

In a decade, we see a world where Anvi humanoids stand shoulder-to-shoulder with technicians on offshore rigs, lunar rovers harvest regolith for in-situ manufacturing, and autonomous rescue crawlers are pre-positioned in every disaster-prone zone — ready to roll before the first siren sounds. Our dream is simple and audacious: wherever the work is too distant, dirty, or dangerous for humans, an Anvi robot will be there first — clearing the way so people can create, heal, and explore without fear.

In 10 years, Anvi will be India’s first vertically integrated ‘imagination engine’ — a constellation of companies that turns moon-shots into main-street realities. Our chips will power the world’s smartest sensors, our green-hydrogen micro-grids will light remote villages, our AI will guide surgeons and spacecraft alike, our textiles will blend heritage with circular sustainability, and our studios will let children pilot virtual rovers across real Martian terrain.

United by one purpose — to elevate human potential while safeguarding the planet — Anvi will stand as proof that a startup born in Hyderabad can inspire, invent, and lead on a truly planetary scale.