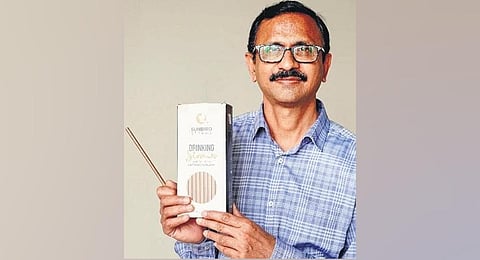

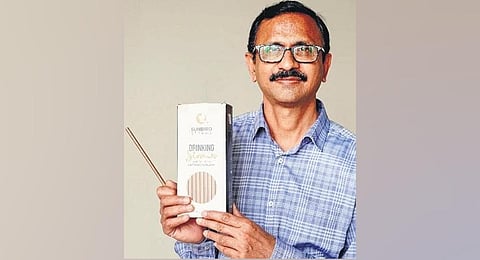

BENGALURU: The tall stately coconut trees that sway to the music of the tropical winds with long, slender fronds, valuable timber, versatile fibre and nutritious fruit, lend themselves to many uses for dwellers along the coastal belt. Strolling through a coconut farm in coastal India, one stumbles upon numerous dried coconut leaves which are truly multitudinous. Saji Varghese, a Bengaluru-based professor from Christ University, had a different plan for the leaves in an urban setup. Wandering through campus one October day in 2017, he noticed a dried coconut leaflet, one of its leaves facing upwards, curled up like a straw. With strenuous research on the viability and flexibility of coconut straws for two years, he developed the patented multi-layered straw that is chemical-free, anti-fungal and hydrophobic, and in 2020, established Sunbird Straws to use the leaves for global change.

From leaf to straw

A survey of 15 villages in Karnataka found that they were either burnt or used in the hearth. Saji says that about 150-200 straws can be made from one dried leaf.

The straws are processed at five production units at Kasargod, Tuticorin, Bannur, Mellahalli and Nagercoil, all of which have sufficient raw materials. The production process involves a hub-and-spoke model. The hubs are straw production centres at Kasargod, Tuticorin and Bannur; the spokes are leaf processing centres at Mellahalli and Nagercoil, which house leaf cleaning and width-cutting machines.

At the spokes, the leaves are cleaned through a jet wash process, post which they are cut to a precise length and width, depending on the diameter of the straw. The leaves are knurled and scraped to give better adhesion, and finally bundled before sending it to the next phase of production. At the hubs, the bundled leaflets are used to make a spiral inner layer and two outer leaflets are stuck longitudinally, with food-grade water-based adhesive sandwiched between two layers.

Leaves processed at Mellahalli are transported to Bannur, and those cleaned at Nagercoil are transported to Kasargod and Tuticorin. The straws are customisable to varying lengths and diameters, ranging from 4mm to 12 mm to suit different beverage needs. “When we first started in 2020, we developed a first-generation tabletop machine that made one straw in 45 seconds. But three months ago, we developed the conveyor system which produces one straw in two seconds,” says Chirag MG, who leads innovations of the company.

Empowering rural women

The primary objective of Sunbird Straws was to replace plastic and paper straws, employ rural women and reduce carbon emissions when the leaves were burnt. “The company has helped women who have never worked, find jobs for themselves and live independently,” says Fousal Haque, who manages the business operations. Moreover, the women live close to the hub and spoke centres, thus avoiding long commutes. Sukhanya (54) who works at Bannur, says she never had the opportunity to work or leave her house, but now she feels independent. Sunanda (38) from Bannur adds that she enjoys coming to work because it does not involve any travel. “I cook, clean, send my children to school and walk to the production centre. Every month, when I receive Rs 5,000, I feel satisfied. Working at the company has also changed my status in the village,” she adds.

Striving to include women in the mainstream, Sandeep, who trains women for the company, says he travels across villages in Kerala, Karnataka and Tamil Nadu to encourage women to take up straw making. Women are trained in two batches for ten days, each comprising 15 women.

Moreover, restaurants and star hotels like Four Seasons, Leela Palace Grand Mercure in Bengaluru, and CGH Earth Pan India have been attracted to the eco-friendly approach. Besides receiving orders from within the country, the straws are in demand in Spain, Germany, Australia, the US, the UK and the UAE.

Sharath, bar manager at Four Seasons, Bengaluru, says they order 2,000-3,000 straws monthly and eventually plan to promote the idea abroad. “We are glad to be a part of this eco-friendly approach and we don’t plan to go back to plastic or paper straws,” he adds.

SHOOTING STRAWS