BENGALURU: Researchers at the Indian Institute of Science (IISc) have fabricated a device to increase or ‘up-convert’ the frequency of short infrared light to the visible range. The human eye can only see light at certain frequencies (called the visible spectrum), the lowest of which constitutes red light.

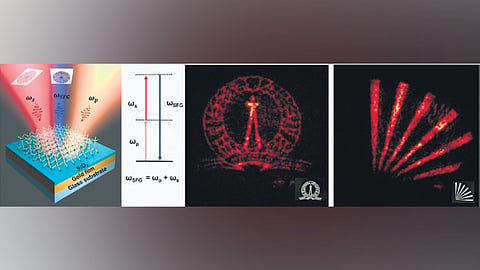

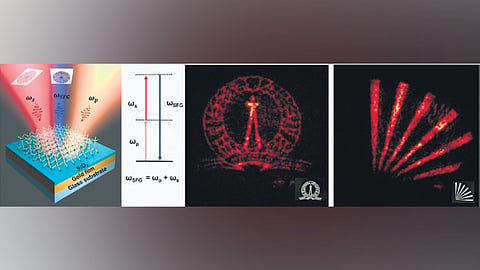

Up-conversion of light has diverse applications, especially in defence and optical communications. The IISc team used a 2D material to design what they call a non-linear optical mirror stack to achieve this up-conversion, combined with wide-field imaging capability. The stack consists of multi-layered gallium selenide fixed to the top of a gold reflective surface with a silicon dioxide layer sandwiched in between, said a press release from IISC.

Traditional infrared imaging uses exotic low-energy bandgap semiconductors or micro-bolometer arrays, which usually pick up heat or absorption signatures from the object being studied. Infrared imaging and sensing are useful in diverse areas, from astronomy to chemistry. However, existing infrared sensors are bulky and not very efficient. They are also export-restricted because of their utility in defence, the release added.

The method used by the IISc team involves feeding an input infrared signal along with a pump beam onto the mirror stack. The nonlinear optical properties of the material constituting the stack result in a mixing of the frequencies, leading to an output beam of increased (up-converted) frequency, but with the rest of the properties intact.

Using this method, IISC team were able to up-convert infrared light of wavelength around 1550nm to 622nm visible light.

“This process is coherent – the properties of the input beam are preserved at the output. This means that if one imprints a particular pattern in the input infrared frequency, it automatically gets transferred to the new output frequency,” explains Varun Raghunathan, associate professor in the Department of Electrical Communication Engineering (ECE) and corresponding author of the study published in Laser and Photonics Reviews.