ISRO achieves breakthrough in Semicryogenic engine development for Launch Vehicle Mark-3

BENGALURU: The Indian Space Research Organisation (ISRO) on Saturday announced significant progress in the design and development of a Semicryogenic engine or Liquid Oxygen / Kerosene engine, with a high thrust of 2000kN that will power the Semicryogenic booster stage of the Launch Vehicle Mark-3 (LVM3).

Specifying that the test demonstrated the smooth ignition and boost strap mode operation of the engine over a test duration of 2.5 seconds, ISRO said the objective was to validate the integrated performance of critical subsystems, such as pre-burner, turbo pumps, start system and control components, by carrying out a hot-firing for 2.5 seconds.

“The test proceeded as predicted, and all the engine parameters were as expected. With this, ISRO is further planning a series of tests on the Power Head Test Article (PHTA) to fine-tune the performance, before realisation of the fully-integrated engine,” it added.

Accordingly, the first major breakthrough in the Semicryogenic engine development programme was achieved on March 28, when the first successful hot test of Engine PHTA, was carried out at the ISRO Propulsion Complex (IPRC) in Mahendragiri, Tamil Nadu.

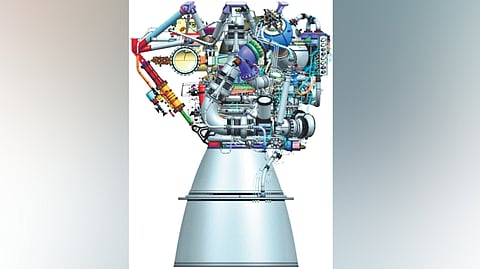

Noting that its Liquid Propulsion Systems Centre (LPSC) is developing the Semicryogenic propulsion engine and stage, ISRO said the stage (SC120) powered by the 2000kN semi-cryogenic engine (SE2000), will replace the present core liquid stage (L110) of LVM3 for payload enhancement, and power the booster stages of future launch vehicles.

Non-toxic and non-hazardous propellants (liquid oxygen and kerosene) are employed in Semicryogenic propulsion, which will deliver higher performance, compared to the L110 stage.

“Induction of the Semicryogenic propulsion system, along with an uprated cryogenic stage in the LVM3 vehicle enhances its payload capability from 4 tonne to 5 tonne in GTO,” the space agency said in a statement.

Major subsystems of the SE2000 engine include thrust chamber, pre-burner, turbo pump system, control components and startup system. The engine works with a complex oxidiser-rich staged combustion cycle, with high chamber pressure of 180 bar (with propellant feed system delivering pressures up to 600 bar), and specific impulse of 335s.

“The complex engine hardware uses special materials to withstand the high temperature and oxidiser-rich combustion. The hardware, along with space-grade kerosene, are realised in partnership with Indian industry. The development of this engine in these high thrust levels is highly challenging and very few nations have this technology,” ISRO stated.