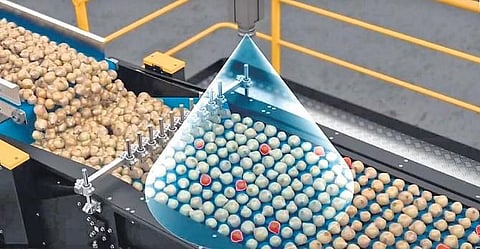

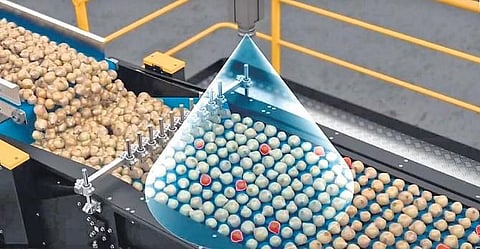

The next time you toss Magic Masala into a pan of boiling water with instant noodles, think about its passage from conveyor belt to bowl. First, it has to pass a stringent quality test before the ‘ok tested’ sticker is slapped on. All along, the watchful eyes of an AI-aided system, which can analyse half a million images in a second are following the production process.

Life has changed in the retail world after Constems-AI, a Noida-based vision inspection company, was hired by corporate giants such as P&G, Unilever and ITC as the official quality checker of their products. Currently, the company is monitoring over 300 products, from inhalers to sanitary napkins and mosquito repellents. Constems derives its name from ‘connected systems’ and was founded in 2017 by IIM Lucknow graduates Amit Singh and Amit Srivastava. But it was in the middle of 2022 when its inspection systems, CAI-netics, got a software upgrade, which boosted its capacity to handle over 8,000 products.

“With more Indian companies having global ambitions, stringent assessment of their products is mandatory. Here, technology comes into the scene,” says Srivastava. Most companies have basic cameras monitoring their product lines. “All that we do is to connect their data to our servers which analyse the information and give solutions where necessary,” Singh explains, giving the example of a soap bar.

Their platform, using a camera and back-end technology, can read the length, breadth, height, volume and colour of the bar, and even its wrapper. “Human beings may be okay if the soap cake is a wonky rectangle or has chipped edges, but AI is unforgiving. It won’t allow a poor-quality product to escape its monitoring. Only the best product will reach the market,” elaborate the co-founders, adding the company works on the principle that AI + System Automation - Human Intervention = Highest level of accuracy.

Didn’t products have a QC mark even five years ago? What’s the big deal with AI intervention? “Products keep moving at such a rapid pace on conveyor belts—300 units every second across their platform—that the human eye cannot keep up with. Previously, companies would take care of the inputs right at the beginning to ensure the quality of products. However, no mechanism existed to address errors in product shape, colour, volume and texture. Dedicated personnel had to physically stand by the conveyor belt to manually monitor the flow and later take the product away. AI is their faster and cheaper replacement,” says Singh.

Constems-AI is currently working on technology that could relieve overworked airport security officers from manually inspecting luggage on conveyor belts. “Hundred per cent AI-based security means zero chances of error, faster inspection and more convenience for passengers. Most importantly, it is non-intrusive. Nobody will rummage through your suitcase. Instead, it’ll be a machine, which is smarter than most humans will be going through your stuff,” grins Singh.